Sustainability

Apparel manufacturing is getting well-deserved scrutiny for its impact on our planet’s resources and factory worker conditions. At Free Reign, we’re deeply committed to making environmentally and socially-sound decisions throughout our business – and to push our company and the apparel industry to the next frontier of sustainability practices.

Product quality and longevity are core to Free Reign’s environmental commitment. Our focus on craft manufacturing of enduring wardrobe staples is the antithesis of fast fashion and ubiquitous consumption.

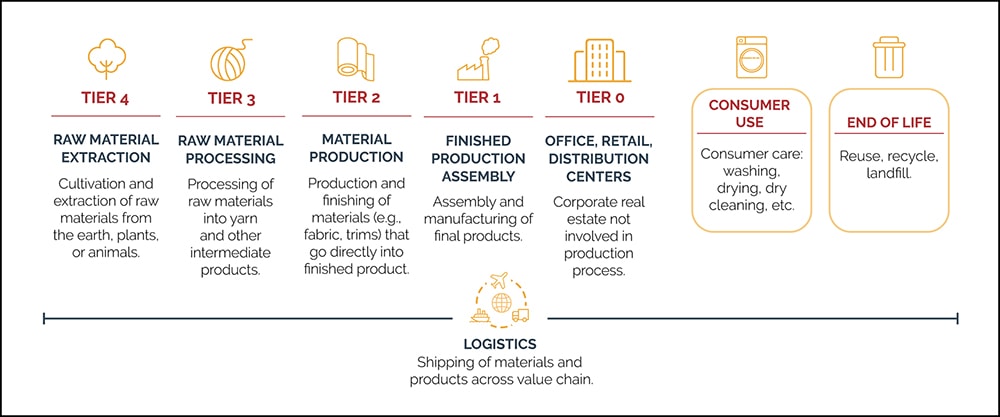

To address the environmental footprint of apparel, businesses and consumers must consider the entire chain of activities from product design and materials selection to how a garment is cared for during its use and end of life. In between is a dizzying array of choices about factory partners, dyeing and finishing methods, packaging materials, shipping logistics, and where and how to shop. Free Reign’s commitments along this apparel “value chain” are described below.

Environmentally-Sensitive Yarns and Fabrics

The majority of our Everyday Tank Top is made from renewable materials of botanic origin. 73% of the outer tank is made from TENCEL™ lyocell and 84% of the inner bra lining is made of TENCEL™ modal. These yarns are derived from wood-based cellulosic fibers supplied by Lenzing AG, an Austrian company with a strong environmental track record. Lenzing sources fibers from forests that are certified as sustainably managed by the Forest Stewardship Council (FSC). Ancient, endangered, and high conservation value forests are off-limits. TENCEL™ fibers – mostly from Beech, Spruce, and Eucalyptus trees – produce smooth yarns that are breathable, cool and dry, and largely resistant to pilling, which is a plus for longevity.

Converting wood into a fiber that can be spun into yarn takes an industrial process requiring energy and chemicals, and that can’t be overlooked. Lenzing’s lyocell uses a closed-loop system in its pulp-dissolving process, recovers solvents for re-use; and with Lenzing’s Modal converts wood byproducts to bioenergy to lower its manufacturing carbon footprint.

The remaining fabric content of the Free Reign Everyday Tank Top is nylon and spandex. These yarns provide stretch and durability, but they are derived from fossil fuel based-synthetic materials. We plan to replace these yarns with recycled options or bio-based alternatives as they become available. As a small brand, our quantities often don’t meet minimum purchase requirements, but we’ll keep you posted as we make progress on this front.

TENCEL™ is a trademark of Lenzing AG.

Low-Impact Garment Care

Our recommended garment care – wash in cold water and air-dry flat – is intended to be gentle on your tank top and our environment. Skipping hot water and the dryer will also cut down on energy costs and carbon dioxide emissions if you get your energy from fossil fuels. We encourage the use of a lingerie bag to promote better care and longer wear, along with your favorite environmentally-friendly laundry detergent.

Eco-Minded Packaging

Thin plastic “polybags” that protect apparel products during shipment from the factory to retail outlets and distribution centers are an undesirable – yet essential – requirement – even for Brands that are the most dedicated to sustainability. The same is true for the mailer that delivers garments to your door. A product that arrives to the customer damaged is unacceptable and a waste of precious resources. Finding good alternatives isn’t easy.

After much research, we selected BioFlex™, a polybag made from sugar cane by Avery Dennison. BioFlex™ has many advantages over a plastic bag made from virgin petroleum-based materials. Foremost, sugar cane is a renewable resource. And while agriculture has its own set of environmental impacts, Avery Dennison sources its sugar cane from growers in Brazil, who have been producing this crop for many years, so no forest has been cleared or other food crops converted to grow it. The growers rely on rain-fed water, not irrigation which can divert water from human consumption and other important needs.

Producing a BioFlex™ bag also removes more carbon dioxide from the atmosphere than it emits. Carbon is sequestered by the sugar cane plant when it grows, and the unused plant waste from the sugar cane is used for biomass energy production in the Brazilian national energy grid. Compared to producing the ingredients in Avery Dennison’s virgin plastic polybag, there is a 100% reduction in fossil fuel energy. As with most options, BioFlex™ isn’t perfect. It is not yet compostable, but it is 100% recyclable in plastics recycling programs.

BioFlex™ polybags cost roughly fifty percent more than conventional plastic bags, but moving our economy away from relying on extraction of finite resources to renewable materials is a big shift we all need to make.

If you order our product online, our warehouse will ship your purchase to you in a 100 percent recycled plastic poly mailer made by EcoEnclose, a Colorado-based company dedicated to “developing and offering the world’s most sustainable ecommerce packaging solutions.” Our mailer features a dual peel and seal closure that allows it to be reused for an exchange, return, or any other shipment you may have. When it can no longer be reused, you can recycle it in thin film plastic recycling programs commonly found at local grocery stores and big box retailers.

If there is no thin film plastic recycling program near where you live, EcoEnclose will take it back and make sure it gets to recyclers, who typically convert it into plastic pellets to be reused in other products or sell it to makers of composite lumber. You can fill our mailer with other #2 and #4 plastic film that you wish to recycle and send it to EcoEnclose, ATTN: Poly Take Back, 416 South Taylor Avenue, Louisville, CO 80027. A guide to the types of packaging that are recyclable in thin film recycling can be found at this link. When recycling plastic mailers, you need to cut out any shipping labels that are made of foil or plastic, but paper ones can remain and will not contaminate the recycling process.

At Free Reign, the small measures we implement matter to us too. Our hang tag and the limited amount of printed collateral we send out with our Tank Tops are all printed on FSC certified paper.

In each stage of a garment’s life, there are opportunities to reduce impacts on the environment.

Source: World Resources Institute

Sustainability

Apparel manufacturing is getting well-deserved scrutiny for its impact on our planet’s resources and factory worker conditions. At Free Reign, we’re deeply committed to making environmentally and socially-sound decisions throughout our business – and to push our company and the apparel industry to the next frontier of sustainability practices.

Product quality and longevity are core to Free Reign’s environmental commitment. Our focus on craft manufacturing of enduring wardrobe staples is the antithesis of fast fashion and ubiquitous consumption.

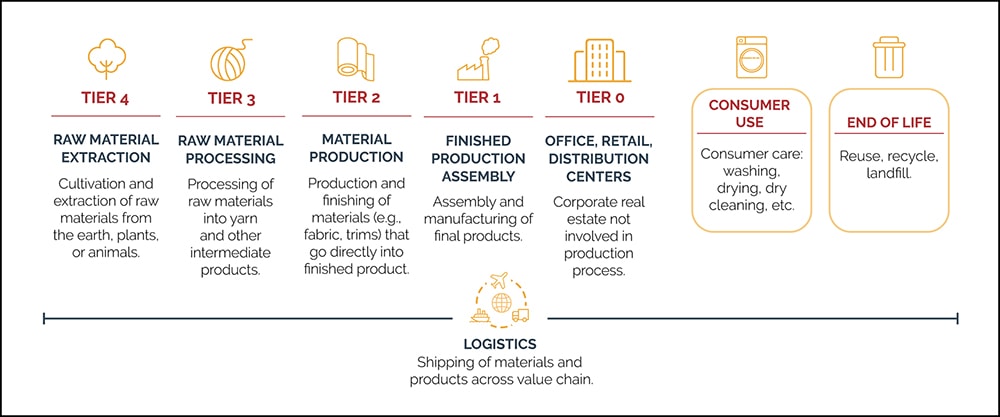

To address the environmental footprint of apparel, businesses and consumers must consider the entire chain of activities from product design and materials selection to how a garment is cared for during its use and end of life. In between is a dizzying array of choices about factory partners, dyeing and finishing methods, packaging materials, shipping logistics, and where and how to shop. Free Reign’s commitments along this apparel “value chain” are described below.

Environmentally-Sensitive Yarns and Fabrics

The majority of our Everyday Tank Top is made from renewable materials of botanic origin. 72% of the outer tank is made from TENCEL™ lyocell and 84% of the inner bra lining is made of TENCEL™ modal. These yarns are derived from wood-based cellulosic fibers supplied by Lenzing AG, an Austrian company with a strong environmental track record. Lenzing sources fibers from forests that are certified as sustainably managed by the Forest Stewardship Council (FSC). Ancient, endangered, and high conservation value forests are off-limits. TENCEL™ fibers – mostly from Beech, Spruce, and Eucalyptus trees – produce smooth yarns that are breathable, cool and dry, and largely resistant to pilling, which is a plus for longevity.

Converting wood into a fiber that can be spun into yarn takes an industrial process requiring energy and chemicals, and that can’t be overlooked. Lenzing’s lyocell uses a closed-loop system in its pulp-dissolving process, recovers solvents for re-use; and with Lenzing’s Modal converts wood byproducts to bioenergy to lower its manufacturing carbon footprint.

The remaining fabric content of the Free Reign Everyday Tank Top is nylon and spandex. These yarns provide stretch and durability, but they are derived from fossil fuel based-synthetic materials. We plan to replace these yarns with recycled options or bio-based alternatives as they become available. As a small brand, our quantities often don’t meet minimum purchase requirements, but we’ll keep you posted as we make progress on this front.

TENCEL™ is a trademark of Lenzing AG.

Low-Impact Garment Care

Our recommended garment care – wash in cold water and air-dry flat – is intended to be gentle on your tank top and our environment. Skipping hot water and the dryer will also cut down on energy costs and carbon dioxide emissions if you get your energy from fossil fuels. We encourage the use of a lingerie bag to promote better care and longer wear, along with your favorite environmentally-friendly laundry detergent.

Eco-Minded Packaging

Thin plastic “polybags” that protect apparel products during shipment from the factory to retail outlets and distribution centers are an undesirable – yet essential – requirement – even for Brands that are the most dedicated to sustainability. The same is true for the mailer that delivers garments to your door. A damaged product that arrives to the customer damaged is unacceptable and a waste of precious resources. Finding good alternatives isn’t easy.

After much research, we selected BioFlex™, a polybag made by from sugar cane by Avery Dennison. BioFlex™ has many advantages over a plastic bag made from virgin petroleum-based materials. Foremost, sugar cane is a renewable resource. And while agriculture has its own set of environmental impacts, Avery Dennison sources its sugar cane from growers in Brazil, who have been producing this crop for many years, so no forest has been cleared or other food crops converted to grow it. The growers rely on rain-fed water, not irrigation which can divert water from human consumption and other important needs.

Producing a BioFlex™ bag also removes more carbon dioxide from the atmosphere than it emits. Carbon is sequestered by the sugar cane plant when it grows, and the unused plant waste from the sugar cane is used for biomass energy production in the Brazilian national energy grid. Compared to producing the ingredients in Avery Dennison’s virgin plastic polybag, there is a 100 percent reduction in fossil fuel energy. As with most options, BioFlex™ isn’t perfect. It is not yet compostable, but it is 100 percent recyclable in plastics recycling programs.

BioFlex™ polybags cost roughly fifty percent more than conventional plastic bags, but moving our economy away from relying on extraction of finite resources to renewable materials is a big shift we all need to make.

If you order our product online, our warehouse will ship your purchase to you in a 100 percent recycled plastic poly mailer made by EcoEnclose, a Colorado-based company dedicated to “developing and offering the world’s most sustainable ecommerce packaging solutions.” Our mailer features a dual peel and seal closure that allows it to be reused for an exchange, return, or any other shipment you may have. When it can no longer be reused, you can recycle it in thin film plastic recycling programs commonly found at local grocery stores and big box retailers.

If there is no thin film plastic recycling program near where you live, EcoEnclose will take it back and make sure it gets to recyclers, who typically convert it into plastic pellets to be reused in other products or sell it to makers of composite lumber. You can fill our mailer with other #2 and #4 plastic film that you wish to recycle and send it to EcoEnclose, ATTN: Poly Take Back, 416 South Taylor Avenue, Louisville, CO 80027. A guide to the types of packaging that are recyclable in thin film recycling can be found at this link. When recycling plastic mailers, you need to cut out any shipping labels that are made of foil or plastic, but paper ones can remain and will not contaminate the recycling process.

At Free Reign, the small measures we implement matter to us too. Our hang tag and the limited amount of printed collateral we send out with our Tank Tops are all printed on FSC certified paper.

In each stage of a garment’s life, there are opportunities to reduce impacts on the environment.

Source: World Resources Institute

Sustainability

Apparel manufacturing is getting well-deserved scrutiny for its impact on our planet’s resources and factory worker conditions. At Free Reign, we’re deeply committed to making environmentally and socially-sound decisions throughout our business – and to push our company and the apparel industry to the next frontier of sustainability practices.

Product quality and longevity are core to Free Reign’s environmental commitment. Our focus on craft manufacturing of enduring wardrobe staples is the antithesis of fast fashion and ubiquitous consumption.

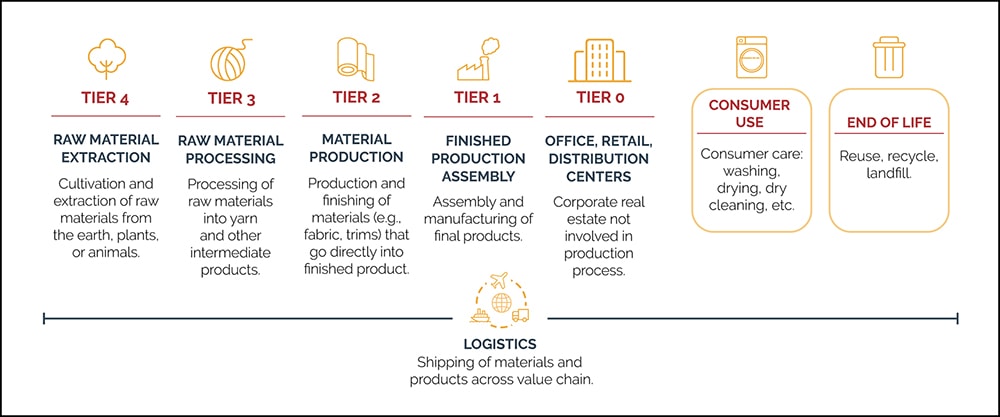

To address the environmental footprint of apparel, businesses and consumers must consider the entire chain of activities from product design and materials selection to how a garment is cared for during its use and end of life. In between is a dizzying array of choices about factory partners, dyeing and finishing methods, packaging materials, shipping logistics, and where and how to shop. Free Reign’s commitments along this apparel “value chain” are described below.

Environmentally-Sensitive Yarns and Fabrics

The majority of our Everyday Tank Top is made from renewable materials of botanic origin. 72% of the outer tank is made from TENCEL™ lyocell and 84% of the inner bra lining is made of TENCEL™ modal. These yarns are derived from wood-based cellulosic fibers supplied by Lenzing AG, an Austrian company with a strong environmental track record. Lenzing sources fibers from forests that are certified as sustainably managed by the Forest Stewardship Council (FSC). Ancient, endangered, and high conservation value forests are off-limits. TENCEL™ fibers – mostly from Beech, Spruce, and Eucalyptus trees – produce smooth yarns that are breathable, cool and dry, and largely resistant to pilling, which is a plus for longevity.

Converting wood into a fiber that can be spun into yarn takes an industrial process requiring energy and chemicals, and that can’t be overlooked. Lenzing’s lyocell uses a closed-loop system in its pulp-dissolving process, recovers solvents for re-use; and with Lenzing’s Modal converts wood byproducts to bioenergy to lower its manufacturing carbon footprint.

The remaining fabric content of the Free Reign Everyday Tank Top is nylon and spandex. These yarns provide stretch and durability, but they are derived from fossil fuel based-synthetic materials. We plan to replace these yarns with recycled options or bio-based alternatives as they become available. As a small brand, our quantities often don’t meet minimum purchase requirements, but we’ll keep you as we make progress on this front.

TENCEL™ is a trademark of Lenzing AG.

Low-Impact Garment Care

Our recommended garment care – wash in cold water and air-dry flat – is intended to be gentle on your tank top and our environment. Skipping hot water and the dryer will also cut down on energy costs and carbon dioxide emissions if you get your energy from fossil fuels. We encourage the use of a lingerie bag to promote better care and longer wear, along with your favorite environmentally-friendly laundry detergent.

Eco-Minded Packaging

Thin plastic “polybags” that protect apparel products during shipment from the factory to retail outlets and distribution centers are an undesirable – yet essential – requirement – even for Brands that are the most dedicated to sustainability. The same is true for the mailer that delivers garments to your door. A damaged product that arrives to the customer damaged is unacceptable and a waste of precious resources. Finding good alternatives isn’t easy.

After much research, we selected BioFlex™, a polybag made by from sugar cane by Avery Dennison. BioFlex™ has many advantages over a plastic bag made from virgin petroleum-based materials. Foremost, sugar cane is a renewable resource. And while agriculture has its own set of environmental impacts, Avery Dennison sources its sugar cane from growers in Brazil, who have been producing this crop for many years, so no forest has been cleared or other food crops converted to grow it. The growers rely on rain-fed water, not irrigation which can divert water from human consumption and other important needs.

Producing a BioFlex™ bag also removes more carbon dioxide from the atmosphere than it emits. Carbon is sequestered by the sugar cane plant when it grows, and the unused plant waste from the sugar cane is used for biomass energy production in the Brazilian national energy grid. Compared to producing the ingredients in Avery Dennison’s virgin plastic polybag, there is a 100 percent reduction in fossil fuel energy. As with most options, BioFlex™ isn’t perfect. It is not yet compostable, but it is 100 percent recyclable in plastics recycling programs.

BioFlex™ polybags cost roughly fifty percent more than conventional plastic bags, but moving our economy away from relying on extraction of finite resources to renewable materials is a big shift we all need to make.

If you order our product online, our warehouse will ship your purchase to you in a 100 percent recycled plastic poly mailer made by EcoEnclose, a Colorado-based company dedicated to “developing and offering the world’s most sustainable ecommerce packaging solutions.” Our mailer features a dual peel and seal closure that allows it to be reused for an exchange, return, or any other shipment you may have. When it can no longer be reused, you can recycle it in thin film plastic recycling programs commonly found at local grocery stores and big box retailers.

If there is no thin film plastic recycling program near where you live, EcoEnclose will take it back and make sure it gets to recyclers, who typically convert it into plastic pellets to be reused in other products or sell it to makers of composite lumber. You can fill our mailer with other #2 and #4 plastic film that you wish to recycle and send it to EcoEnclose, ATTN: Poly Take Back, 416 South Taylor Avenue, Louisville, CO 80027. A guide to the types of packaging that are recyclable in thin film recycling can be found at this link. When recycling plastic mailers, you need to cut out any shipping labels that are made of foil or plastic, but paper ones can remain and will not contaminate the recycling process.

At Free Reign, the small measures we implement matter to us too. Our hang tag and the limited amount of printed collateral we send out with our Tank Tops are all printed on FSC certified paper.

In each stage of a garment’s life, there are opportunities to reduce impacts on the environment.

Source: World Resources Institute